Always read the Operating Handbook before use and follow all

Safety Instructions

- Basic setting up

- Water supply

- Electric supply:connection, extension cables, generator info

- Oil change

- General Safety information

You can skip down to the topic you are looking for by making your selection above,

or scroll down to find out more...

Machines are designed for the pumps inside to be operated laying flat. If your machine has two wheels, it should not be stood up-right to operate.

The transmission is well lubricated when in the horizontal position, adding years to seal service life.

If you are connecting your pressure washer to a tap, then we suggest using as short a possible length of hose to supply the machine water.

Using longer lengths than 3M, can cause a drop in volume of water available at the end.

If your water supply hose is on a reel - it is very important to fully un-wind your low-pressure hose from the reel first, failure to do this can result in a water shortage to your pressure washer.

Kranzle pressure washers as standard come with a fitted standard Hozelock push fitting.

These are adequate for using with a water supply that has 3-5 bar.

If you plan to use your pressure washer on suction, We strongly suggest that you use the 'cap & liner' type fitting that is also supplied in the box! which cannot fall away and let air draw in with the water supply. When you have your gun, lance and hose connected to the machine, your water supply connected, and the electric cable plugged in and in the on position.

Squeeze the trigger gun so that water is coming through the end of your lance, and then turn the pressure washer on using the "on/off" switch.

Information showing you how to set your machine up taken from an operators hand book can be found,

Water supply

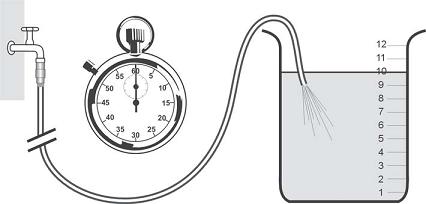

It is important that your pressure washer has sufficient water to run properly. If the pump can not get enough water through

it's supply hose damage will occur to the transmission. Always test this

by running your hose into a measured container for one minute to make sure there

is at least 10% more water flowing from the end of your hose where you will

connect it to your machine than the machine's output.

Which water fitting to use?

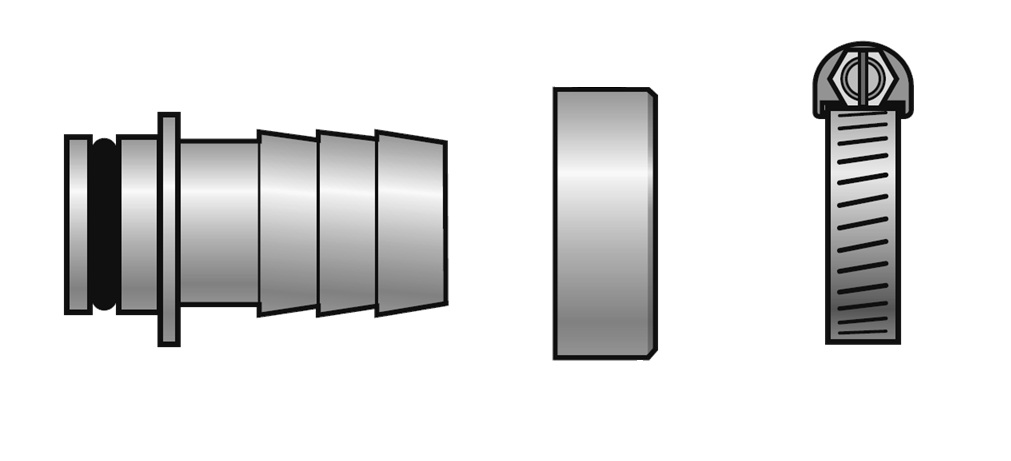

There are two water connection fittings supplied with your Kranzle pressure washer:

Gardena Hozelock fitting Kranzle Cap & Liner fitting

A Gardena Hozelock fitting is supplied and comes fitted to most machines for use straight out of the box, when the supply water from your hose is connected to a tap. A Kranzle Cap & Liner fitting, including a jubilee clip is also provided in the box.

Cap & Liner fittings should always be used when the supply water hose is drawing from a tank.

Gardena hozelock fittings require a degree of water pressure

to form and keep a seal; using a 'push' only fitting when drawing water from a tank, or similar container, may allow air to be drawn in by the pump with

your water supply, causing damage.

Electric supply: connection, extension cables, generator info

Do not use light weight extension cables. Kranzle pressure washer use

industrial grade induction motors and will not run properly on diy type cable

reels. If you need to use an extension cable it must be a 2.5mm cross

section cable.

Generators vary hugely between manufacturers and the actual power that they deliver. It is best to give us a call where we can advise you based on what other users' have experienced to work. It will depend on the machine you have, but we can advise more sensible sized generators than the 3 times starting load normally quoted.

If your machine switches itself off while you are using it DO NOT switch it back

on for 10 minutes. The On/Off switch has a thermal trip in it to help

protect the motor. Allow the machine to cool down for at least 10 minutes

before switching it back on. Try to establish why the motor was over

heating. This could be due to inadequate ventilation, use of an inadequate

extension cable or the pump running in excess of it's normal operating pressure

- in which case check the high pressure nozzle on the end of the lance for a

partial blockage and unscrew the unloader hand wheel on the side of the pump

until the pressure shown on the pressure gauge with the trigger squeezed is

correct for your machine.

Oil change

This does really depend on which machine you have.

There are two standard oil types used in the Kranzle pressure washers: 15W/40 and 10W/60

The oil type, and how much is needed is in the Operators Hand book. There is a list HERE, but there have been changes; so always check your operator handbook, or contact your supplier.

All Kranzles come with the correct level of oil all ready for you to use. We suggest that after the first 50 operating hours, taking care to ensure any waste oil is responsibly disposed of, drained from the oil resevoir. Then add a little new oil, seal up the oil chamber and turn it on for just a second or two. Drain, and repeat until what comes out is 'nice'.

Then fill to the correct level as per your operators hand book.

It only takes a few parts per thousand of water to emulsify oil and the only real way of getting all traces out of a water contaminated oil chamber is to strip down the machine, and wipe clean all of the parts. It is not the colour of the oil that is important though, it is the consistency of the oil. Oil is only in there for heat dispersal, and lubrication for the transmission parts.

General Safety information

A portion of the general safety information provided from the operator hand book can be found, HERE, but for individual machine specifics please refer to your operators hand book.

Problems? Go to Parts Diagrams also visit Servicing Dealers If you have not found what you were looking for, please email us with your query or call 0844 310 9107